What’s MYSPOT? Technology

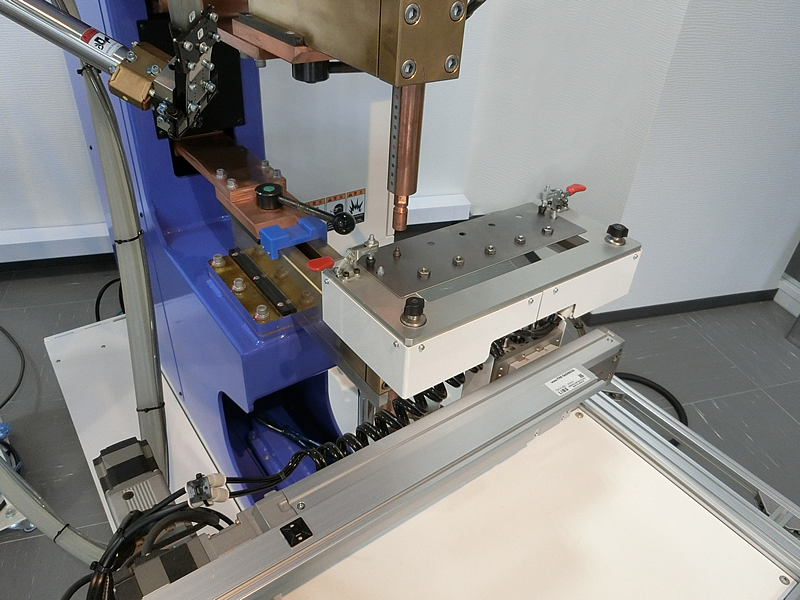

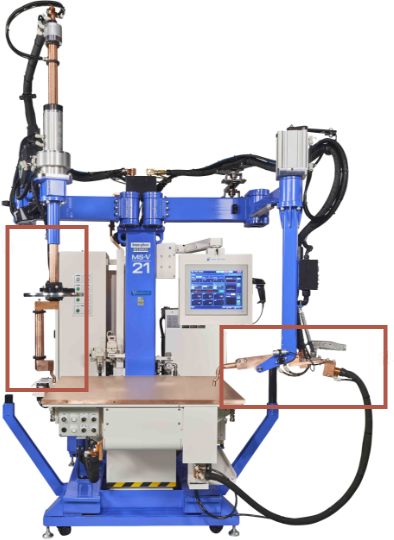

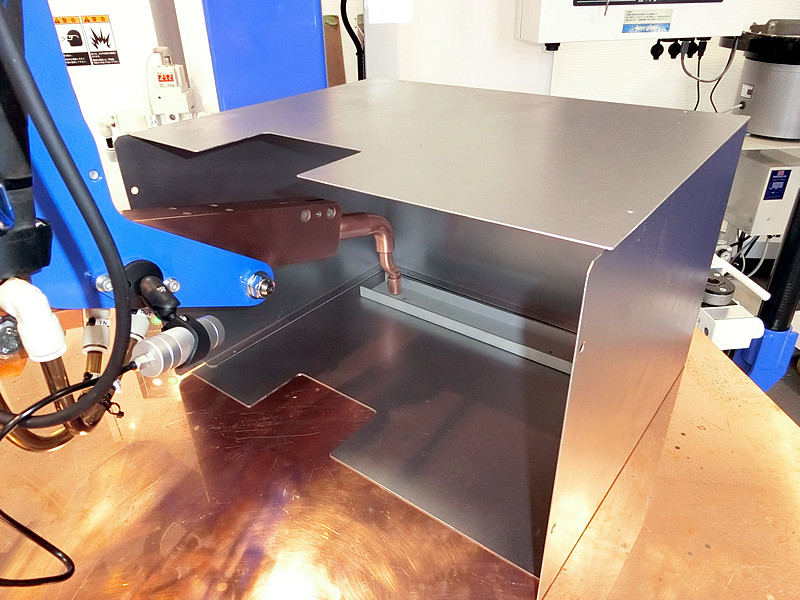

Table Spot Welder

The NK-21/-03/-71 series of table spot welders are innovative welding machines equipped with a welding gun with articulated arms and a table-type electrode. Equipped with functions that reduce conventional post-welding processes such as sanding, the NK-21/-03/-71 series will contribute to the improvement of tomorrow’s welding workplaces.

Vertical gun

The V-gun is the most suitable gun for welding deep box products that are closed on all sides. The tip of the gun has a crank shape that makes it easy to aim at the edge of the workpiece. It can also apply pressure directly to the surface, making it ideal for welding nuts, screws, and bosses.

Horizontal gun

The H-gun is a long horizontal gun suitable for welding complex workpiece shapes and deep areas. It is possible to weld as desired while moving the gun freely on the table electrode.

* The sales model differs depending on the overseas area.

-

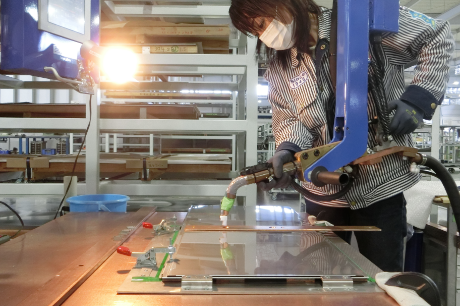

Labor-saving

With the table spot welder, if the workpiece can be placed on the table-type electrode, it can be welded without the use of auxiliary personnel. The two guns move freely, allowing easy access to the desired welding point by one person.

-

Reduces set-up time

Unlike conventional stationary spot welders, this system significantly reduces the need for ancillary work such as electrode adjustment and workbench set-up, contributing to a reduction in overall welding man-hours.

-

Easy to set welding conditions

The welding conditions for MYSPOT can be easily set using the touch panel system. By simply selecting “material” and “plate thickness,” the recommended conditions can be called up, and current and welding time can be adjusted smoothly. Anyone can easily configure the settings, and even inexperienced welders can become welders of the future.

-

Comfortable working position

There is no need to hold the workpiece during welding; it can simply be placed on the table-type electrode. Pressurization is also automatic, greatly reducing the physical burden on the operator. The amount of work that can be done per unit time is also dramatically increased.

-

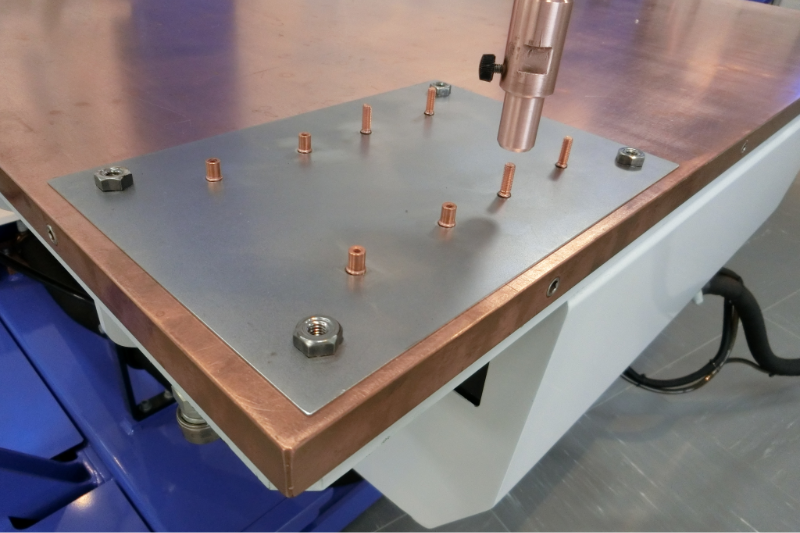

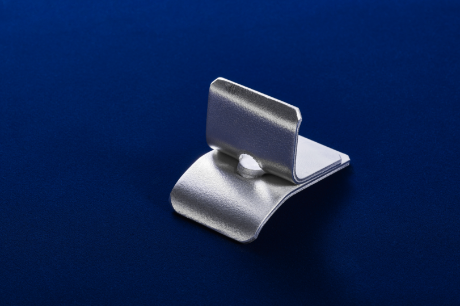

Can also weld nuts and screws

Welding can be done efficiently by changing the electrode tip according to the type and size of nut, etc.

-

Reduction of finishing and post-processing

The table-type electrode produces flatter cosmetic surface indentations and reduces distortion of the workpiece, contributing to less need for post-processing after welding. Furthermore, by applying High-Speed Spot Welding Technology, the cosmetic surface indentation is reduced by 1/3 (compared to our conventional products), and burn and heat distortion are also reduced, which greatly reduces finishing work.

Static-pressure Spot WelderNK-08 SERIES

The NK-08 series of static pressure spot welders are the latest in stationary spot-welding machines, incorporating Koyo’s ideas into the traditional stationary type. This series is ideal for workpieces that can be held in the hand, and when combined with the special jigs that are Koyo’s forte, it can support your workplace as an original piece of equipment.

Safe static pressure mechanism

The gun is equipped with a static pressurization mechanism that allows the operator to firmly aim at the welding point with a two-press foot switch. Pressurization is applied after positioning, allowing welding work to proceed safely.

Quick set-up with square horn

The upper and lower square horns of this welding machine can be adjusted quickly and easily with a one-touch lever that eliminates shaking. They also offer operability with excellent sensory feedback.

* The sales model differs depending on the overseas area.

-

Easy to set welding conditions

The welding conditions for MYSPOT can be easily set using the touch panel system. By simply selecting “material” and “plate thickness,” the recommended conditions can be called up, and current and welding time can be adjusted smoothly. Anyone can easily configure the settings, and even inexperienced welders can become welders of the future.

-

Can be equipped with a power source for a maximum aluminum plate thickness of 3 mm

The -08 series can be equipped with a welding power source for a maximum aluminum plate thickness of 3 mm. Please consider this model when welding aluminum products. Although this series offers high output, it is energy-saving and can be installed with a 50 A power incoming unit.

-

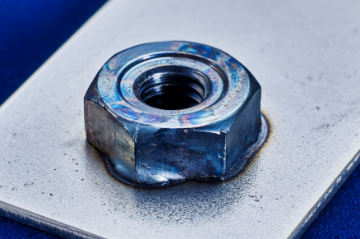

Clean welding of nuts and studs

Please consider this series for welding nuts and studs. By using together with High-Speed Spot Welding Technology, the welding finish will be greatly improved.

-

Combination of welding machine and jig improves workplace performance

By combining the 08 series with special jigs such as the parts feeder or workpiece transport device, you can turn it into your own original production facility.

Compared to the introduction of large-scale automated equipment, the initial cost can be reduced, making it ideal as an entry model for process automation.