What’s High-Speed Spot Welding Technology? Technology

-

01

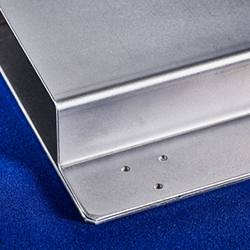

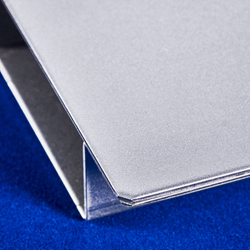

Clean and Strong

With High-Speed Spot Welding Technology, you can control large currents in units of 1/1000 of a second to complete spot welding work in an extremely short time while controlling spatters.

Compared to conventional current control, this technology enables welding in 1/15 to 1/20 of the energizing time.

By completing the spot welding work in a very short time, burn marks, heat distortion, and sheet separation (sheet lifting) are greatly reduced while maintaining strength.Conventional method

High-Speed Spot Welding Technology

Welding surface

Decorative surface

-

02

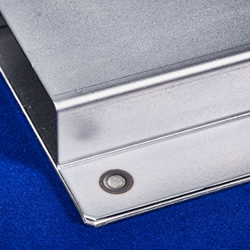

Reduction of secondary processing after spot welding

High-Speed Spot Welding Technology aims to reduce the need for secondary operations such as sanding, burn removal, and distortion correction, which are commonly performed after spot welding.

Why not try High-Speed Spot Welding Technology, which is “Clean and Strong,” to achieve “finishless” welding?Conventional method

High-Speed Spot Welding Technology

Welding surface

Decorative surface

-

03

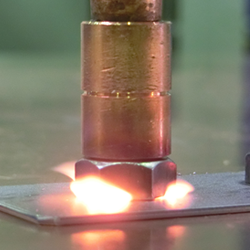

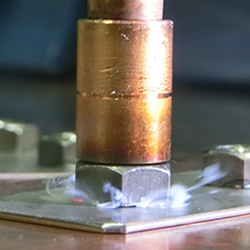

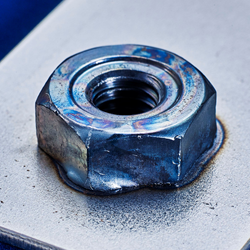

Combination of High-Speed Spot Welding Technology and projection enables an even more clean appearance

The instantaneous power of High-Speed Spot Welding Technology with its high current and extremely short time energization is a perfect match for projection welding.

Applying this technology to materials such as weld nuts, plated steel sheets, and mesh materials enables welding with even better aesthetics.Conventional method

High-Speed Spot Welding Technology

Welding surface

Decorative surface

-

04

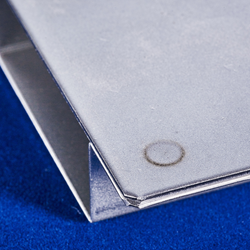

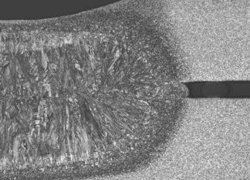

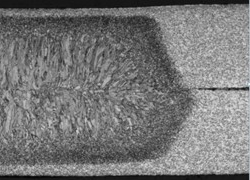

Reduction of sheet separation

Heat is always generated during spot welding.

The heat generated during the welding process distorts the material and creates gaps between the plates, a phenomenon known as sheet separation.

High-Speed Spot Welding Technology completes welding in a shorter time than conventional current control, thus reducing the area affected by heat and reducing sheet separation.

The result is a higher precision product with less distortion.Conventional method

High-Speed Spot Welding Technology

-

05

Energy saving with high-speed

weldingHigh-Speed Spot Welding Technology allows for a shorter energizing time and a reduction in energy consumption to about 1/7 compared to conventional models (compared to our conventional products).

Conventional method

High-Speed Spot Welding Technology